Polyvinyl alcohol (PVA) is a long-used additive in textiles and papermaking. It's great because it makes strong films, sticks well, dissolves in water, and is safe for the environment. However, to meet the increasingly stringent demands of modern industry for material performance, processing efficiency, and environmental responsibility, traditional PVA is being replaced by modified PVA. Modified Polyvinyl Alcohol optimizes its structure and functionality through chemical and/or physical means, enabling it to offer unmatched advantages over traditional PVA in two key industries.

1. Textile Industry: A Performance Leap from Sizing to Printing and Dyeing

In textiles, PVA mainly sizes warp yarns. It coats the yarn with a thin layer before weaving, which makes the yarn stronger and less likely to break. This makes weaving easier and improves the quality of the fabric.

- High-Performance and Efficient Warp Sizing

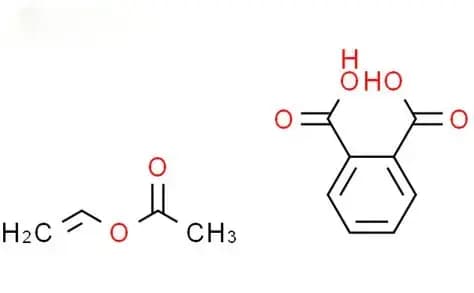

Enhanced Adhesion and Abrasion Resistance: By introducing hydrophilic or hydrophobic groups and performing graft copolymerization, PVA can enhance its affinity with various fibers (such as polyester, cotton, and blends), resulting in a tougher and more abrasion-resistant sizing film. This means that yarn breakage rates are further reduced on high-speed, high-density looms, significantly improving production efficiency.

Better Sizing and Eco-Friendly Solution: Regular PVA needs high heat and strong alkalinity to remove sizing, which wastes energy and makes dirty water. Modified PVA, with its sizing properties, can be taken off fast with less harsh conditions. This cuts washing time, saves energy, and reduces wastewater treatment, fitting well with green textile plans.

Antistatic and Smooth Properties: Modified PVA can really help with static in yarns. They stop static from building up when the yarn rubs together fast during weaving. This keeps the weaving process running smoothly.

- Diverse Applications in Printing, Dyeing, and Finishing

Modified PVA acts as a thickener in printing pastes. It's also a coating and binder for nonwoven materials. This gives textiles special finishes, improving their feel, water resistance, or flame retardancy.

2. Papermaking Industry: A Core Additive for Improving Quality and Functionality

In the papermaking industry, PVA is primarily used for surface sizing and internal sizing/filler retention, playing a decisive role in the printability, strength, and special properties of paper.

- Surface Sizing: Optimizing Printability and Paper Strength

Excellent Film Formation and Ink Resistance: Using special PVA on paper makes a solid, even layer. This stops ink or coatings from soaking in. The result is clearer printing, shinier paper, and a stronger surface. This is particularly important in the production of high-quality coated paper, inkjet paper, and specialty paper.

Improved Wet/Dry Strength: Adding cross-linking or reactive groups to modified PVA lets it make stronger bonds with pulp fibers. This boosts the paper's strength when it's dry or wet.

- Internal Sizing and Functional Paper Manufacturing

Retention and Drainage Aids: Cationic modified PVA can be used as a retention aid to improve the retention of fine fibers and fillers, saving raw materials and improving paper uniformity.

Specialty Paper: In the manufacture of thermal and pressure-sensitive paper, as well as high-barrier food packaging paper, modified PVA, due to its excellent barrier properties (such as low permeability to oxygen and gases) and good biodegradability, is an irreplaceable choice over other polymer materials.

3. Ongoing Green Commitment

The importance of modified PVA lies not only in its high performance but also in its environmental credentials. PVA's inherent biodegradability and water solubility (depending on the degree of polymerization and modification) make it a "green" alternative to some traditional synthetic polymers (such as acrylics and styrenes). Through precise modification, the industry can achieve higher material recycling rates and a lower environmental footprint while ensuring product performance.

Modified PVA(such as Modified PVA 8048) represents a new era of traditional additives and is a key step in the textile and papermaking industries' transition from "manufacturing" to "smart manufacturing." With increasing demands for sustainable development and product quality, research into functionalizing, compounding, and environmentally friendly PVA modifications is expected to continue in-depth, providing a strong impetus for the future development of these two pillar industries.

Website: www.elephchem.com

Whatsapp: (+)86 13851435272

E-mail: admin@elephchem.com