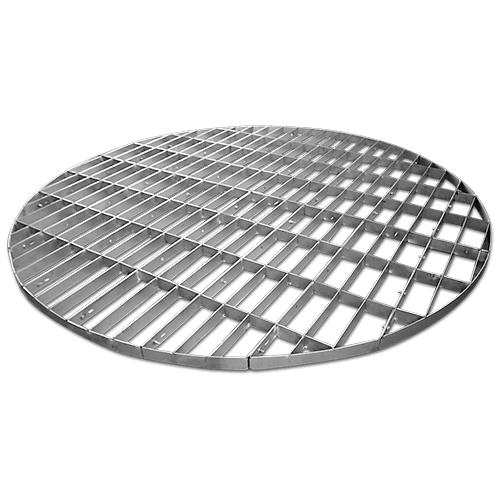

Support Plate:

-

Design:

- Flat or slightly curved plates with openings (holes, slots, or grids) to allow the passage of gas and liquid.

- Typically made from metal, plastic, or composite materials.

-

Function:

- Primary Role: To provide a stable base for the packing material and distribute the weight evenly.

- Flow Distribution: Ensures uniform distribution of gas and liquid across the packing bed.

- Drainage: Allows liquid to drain effectively while preventing excessive hold-up or flooding.

-

Applications:

- Used in both random and structured packing systems.

- Suitable for a wide range of industries, including chemical, petrochemical, and environmental.

-

Advantages:

- Simple and robust design.

- Provides excellent support and drainage capabilities.

Hump Support:

-

Design:

- Curved or arched plates with a "hump" shape, often with openings for gas and liquid flow.

- Made from materials such as metal or plastic.

-

Function:

- Primary Role: To support the packing material while minimizing pressure drop and improving liquid distribution.

- Enhanced Drainage: The hump shape facilitates better liquid drainage and reduces the risk of liquid pooling.

- Gas Flow Optimization: The design allows for smoother gas flow, reducing resistance and energy consumption.

-

Applications:

- Commonly used in columns with high liquid flow rates or where minimizing pressure drop is critical.

- Ideal for applications involving random packing.

-

Advantages:

- Improved liquid and gas distribution compared to flat support plates.

- Lower pressure drop, leading to energy savings.

- Reduces the risk of flooding and channeling.

Key Differences:

-

Design:

- Support plates are typically flat or slightly curved, while hump supports have a distinct arched or hump-like shape.

-

Pressure Drop:

- Hump supports are designed to minimize pressure drop more effectively than flat support plates.

-

Liquid Drainage:

- Hump supports offer better liquid drainage due to their arched design, reducing the risk of liquid hold-up.

-

Application Specificity:

- Support plates are more versatile and widely used, while hump supports are often chosen for specific applications requiring optimized flow and drainage.

Comparison Summary:

| Feature | Support Plate | Hump Support |

|---|---|---|

| Shape | Flat or slightly curved | Arched or hump-shaped |

| Pressure Drop | Higher compared to hump supports | Lower |

| Liquid Drainage | Good | Excellent |

| Applications | General-purpose, wide range | High liquid flow, low pressure drop |