Pall rings and Intalox saddles are both types of random packing used in industrial processes to enhance mass transfer in packed columns. However, they differ in design, performance characteristics, and specific applications. Here’s a detailed comparison:

Design:

-

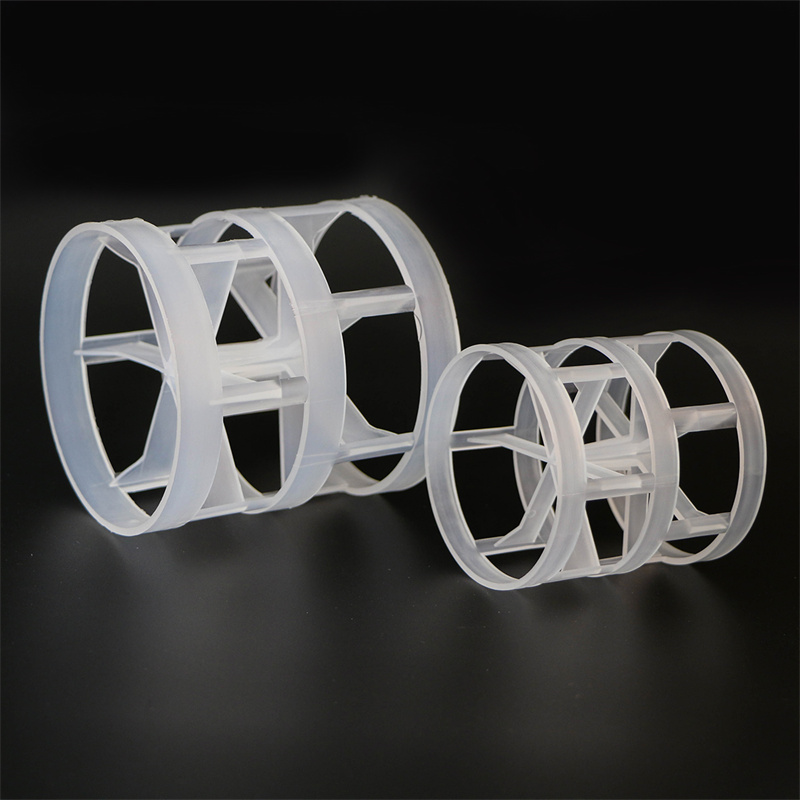

Pall Rings:

Shape: Cylindrical with an open structure and internal struts.

- Surface Area: Provides a high surface area due to the internal and external geometry.

- Material: Made from metal, plastic, or ceramic.

Intalox Saddles:

-

- Shape: Saddle-shaped with a contoured surface and open structure.

- Surface Area: Offers a large surface area due to the saddle shape.

- Material: Typically made from ceramic, plastic, or metal.

Performance Characteristics:

-

Pall Rings:

- Efficiency: High mass transfer efficiency due to excellent gas-liquid contact.

- Pressure Drop: Low pressure drop, making them energy-efficient.

- Capacity: High capacity for gas and liquid flow.

- Mixing: Promotes turbulent flow, enhancing mixing and mass transfer.

-

Intalox Saddles:

- Efficiency: High mass transfer efficiency with good gas-liquid distribution.

- Pressure Drop: Very low pressure drop, even lower than pall rings.

- Capacity: High capacity, often higher than pall rings.

- Mixing: Provides uniform liquid distribution and good mixing.

Applications:

-

Pall Rings:

- Suitable for a wide range of applications, including distillation, absorption, and stripping.

- Often used in processes requiring high efficiency and low pressure drop.

-

Intalox Saddles:

- Ideal for applications requiring very low pressure drop and high capacity.

- Commonly used in distillation, absorption, and other mass transfer operations, especially in processes where minimizing energy consumption is critical.

Advantages:

-

Pall Rings:

- Robust design with high durability.

- Versatile and suitable for various industries and processes.

-

Intalox Saddles:

- Excellent liquid distribution and low pressure drop.

- High capacity and efficiency, making them suitable for large-scale operations.

Summary:

While both pall rings and Intalox saddles are effective in enhancing mass transfer, the choice between them depends on specific process requirements. Pall rings are known for their robustness and versatility, while Intalox saddles are preferred for their superior liquid distribution and extremely low pressure drop. Selecting the appropriate packing can optimize process efficiency and reduce operational costs.