Welcome Inquiry!

Background

Epoxy resin is a very important thermosetting resin because there are many epoxy groups in pure epoxy resin. Therefore, the chemical cross-linking density of the cured structure is high, the molecular chain flexibility is low, and the internal stress is large, resulting in the epoxy cured material being more brittle and having poor impact resistance and fatigue resistance durability.So the application and development of epoxy resin in high-tech fields with durability and reliability requirements are limited. Therefore, it is necessary to toughen and modify epoxy resin while maintaining its excellent properties.

Toughening modification methods

1. Rubber elastomer toughened epoxy resin

Rubber elastomers are the earliest and most widely used tougheners. Rubber elastomers used for toughening epoxy resins are usually reactive liquid polymers (RLP), that is, the end or side groups have active functional groups (such as -COOH, -OH, -NH2, etc.), which can chemically react with epoxy groups. Factors that determine the toughening effect of rubber elastomer:a.The solubility of rubber molecules in uncured EP. b. Whether rubber molecules can precipitate during the curing process of epoxy gel and be evenly dispersed in the ring with appropriate particle size and ideal form. in oxygen resin.

Currently commonly used RLP rubbers and elastomers include amine-terminated nitrile rubber (ATBN), epoxy-terminated nitrile rubber (ETBN), hydroxyl-terminated nitrile rubber (HTBN), carboxyl-terminated nitrile rubber (CTBN), polyester Sulfur rubber (PSR), PUR and silicone rubber (SR), etc. Among them, CTBN contains very polar nitrile groups (-CN) and has good molecular flexibility. Its toughened EP system forms a "sea-island" microscopic phase separation structure that helps improve the toughness of composite materials.

2. Core-shell polymer toughened epoxy resin

Core/shell structure polymer (CSP) toughened epoxy resin technology is used. CSP particles are enriched with different material components inside and outside, resulting in their core and shell having different functions. Compared with the traditional EP/RLP system, due to the good flocculation of the CSP shell, it is incompatible with EP after blending and can form a complete "sea-island" phase separation structure after solidification. By controlling the core-shell material components and particle size, which can significantly improve the toughness of EP.

3. Thermoplastic resin toughened epoxy resin

Due to the low molecular weight of rubber elastomers, their introduction into EP will reduce the strength, modulus and heat resistance of the cured product. In order to solve these problems, researchers have developed high toughness, high strength and high heat resistance properties. The TP toughening EP approach can significantly improve EP toughness. The commonly used TPs include polysulfone (PSF), polyethersulfone (PES), polyetherketone (PEK), polyetheretherketone (PEEK), polyetherimide (PEI), polyphenylene ether (PPO), etc.

4. Thermotropic liquid crystal polymer (TLCP) toughened epoxy resin

Thermotropic liquid crystal polymer (TLCP) is a type of TP with special properties. Its molecular structure contains a certain amount of flexible segments and a large number of mesogenic rigid units (methylstyrenes, esters, biphenyl, etc.), which exhibits high strength and high Excellent mechanical properties such as modulus and self-reinforcement as well as better heat resistance. Liquid crystal epoxy resin (LCEP) has the advantages of both EP and liquid crystal, and has good compatibility with EP and can be used to toughen epoxy resin.

5. Polymer interpenetrating network structure (IPN) toughened epoxy resin

IPN not only improves the impact strength and toughness of composites, but also maintains or even improves their tensile strength and heat resistance. This is because unlike mechanical blends, the polymer component materials in IPN are entangled and penetrated at the molecular segment level, thus showing "forced inclusion" and "synergistic effects"

6. Hyperbranched polymer (HBP) toughened epoxy resin

The mechanism of HBP tougheningepoxy resin is to assemble functional groups in the outer layer of HBP molecules, which reduces the degree of molecular chain entanglement in the system and reduces the crystallinity, thereby regulating the phase structure of EP and improving the toughness of the resin system.

Some scholars have synthesized hyperbranched polyurethane (HBPu) using a quasi-one-step method, and then used it to toughen acid anhydride-cured bisphenol A-type glycidyl ether (DGEBA). Research shows that after the introduction of HBPu, the resin viscosity of the uncured EP system is significantly reduced; the impact properties of cured EP are significantly improved.

7. Nanoparticle toughened epoxy resin

Nanoparticles have become one of the hot topics in recent materials research due to their synergistic effect on both strengthening and toughening of polymers, which is attributed to properties such as nanoparticle surface effects and quantum size effects. Among them, inorganic fillers are widely used because of their low cost, low thermal expansion and shrinkage, and high elastic modulus and impact toughness of the composite materials produced. For example: Nano-zirconia (ZrO2), etc.

Carbon nanomaterials, including CNT and graphene (GE), have a higher surface area to volume ratio due to their unique one- and two-dimensional structures, making them more conducive to improving the mechanics, electricity, thermal and barrier properties of the polymer matrix. Properties are currently a hot research topic in material modification. Due to the low surface activation energy of carbon nanomaterials, their compatibility with EP is not ideal, so researchers modified the carbon nanomaterials for use.

Organic nanoelastomers, such as carboxyl nitrile elastomers, butylbutylene elastomers, etc., in addition to the characteristics of nanomaterials, also have the toughness of elastomers, and have good compatibility with EP. They are a type of elastomer with broad development prospects material.

8. Ionic liquid toughened epoxy resin

Ionic liquids are molten salts composed of inorganic anions and organic cations. They are liquid at or near room temperature. They are recognized as "green materials" because of their non-volatility. Ionic liquids have "designability" and are used as plasticizers, lubricants, nucleating agents and antistatic agents for polymers.

Some scholars have used butane ionic liquids to dope GE-modified EP composites, and their tensile properties and bending properties have also been significantly improved.

9. Composite toughened epoxy resin

With the development of technology, researchers have realized that using two toughening agents in combination has better application effects than a single toughening agent. EP/(GE/KH–GE)/MWCNTs-OH composites were prepared by adding GE and hydroxylated multi-walled CNTs (MWCNTs-OH) to EP. The results show that GE/KH–GE and MWCNTs-OH have a synergistic toughening effect on EP without affecting the mechanical properties of EP.

10. Flexible segment curing agent toughens epoxy resin

Methods for modifying EP based on physical or chemical principles have shortcomings such as complex and lengthy process routes. By using macromolecular curing agents containing flexible segments, after the EP is cured, the flexible segments are naturally bonded to the resin system. In the three-dimensional cross-linked network, on the one hand, it improves the flexibility of the molecules and promotes plastic deformation of the resin structure. On the other hand, the flexible segments also produce microscopic phase separation structures in the resin system, which can alleviate stress concentration. Therefore, flexible segment curing agents can greatly improve the toughness of EP without increasing process complexity.

Compared with traditional rigid aromatic amine curing agents, after curing EP with aromatic amine curing agents (RAn) containing flexible groups such as ether bonds (—O—) and saturated alkane chains [—(CH2)n—], the resin system has a better The tensile properties and impact properties have been improved to a certain extent.

Outlook

With an in-depth understanding of the toughening mechanism and based on the continuously improved material genome technology, on the basis of traditional toughening and reinforcement, new toughening methods/processes and the development of new multi-functional toughening agents can be further improved. Thermal properties and endowed with properties such as thermal conductivity, electrical conductivity, wave absorption, electromagnetic shielding, damping and shock absorption.

Semiconductor devices require the use of semiconductor equipment such as etching machines, photolithography machines, and ion implantation machines. Inside these semiconductor devices, numerous ceramic components are used. Ceramic materials offer excellent properties, including high-temperature resistance, corrosion resistance, high precision, and high strength, making them well-suited for use in semiconductor equipment. Many ceramic components are key parts in semiconductor processes, directly contacting the wafers. They can achieve precise control of wafer surface temperature and rapid heating or cooling.

Semiconductor ceramic components belong to advanced ceramics, typically made from high-purity, ultra-fine inorganic materials, such as alumina (Al₂O₃), silicon carbide (SiC), aluminum nitride (AlN), silicon nitride (Si₃N₄), and yttria (Y₂O₃). The types of semiconductor ceramic components include semiconductor robotic arms, ceramic nozzles, ceramic windows, ceramic cavity covers, porous ceramic vacuum suction cups, and others.

The preparation process for semiconductor ceramic components mainly includes powder preparation, powder molding, high-temperature sintering, precision machining, quality inspection, and surface treatment.

Regarding sintering processes, some ceramic components undergo de-binding followed by sintering, while in others, de-binding and sintering are performed simultaneously. Typically, the de-binding temperature is lower than the sintering temperature and does not exceed 1000°C. High-temperature sintering methods mainly include pressureless sintering, vacuum sintering, and atmosphere sintering. Sintering transforms the ceramic from a green body to a dense structure.

The main sintering processes are as follows:

-

Pressureless Sintering

Pressureless sintering refers to the process where the material is sintered under atmospheric pressure without the application of additional pressure. This is the most commonly used sintering method, typically performed in an oxygen atmosphere or a special gas atmosphere. During pressureless sintering, the formed green body is not subjected to external pressure, and the powder particles aggregate and form crystalline bonds under normal atmospheric pressure.

-

Vacuum Sintering

Vacuum sintering is the process of sintering ceramic green bodies under a vacuum environment. Through physical and chemical actions, the green body is transformed into a dense and hard sintered body. In oxide ceramic bodies, the pores are primarily filled with water, hydrogen, and oxygen, which escape during sintering. However, gases such as carbon monoxide, carbon dioxide, and especially nitrogen are difficult to escape through the pores, leading to reduced density in the final product. Vacuum sintering ensures that all gases are expelled, improving the product's density.

-

Atmosphere Sintering

For ceramics that are difficult to sinter under pressureless sintering, atmosphere sintering is commonly used. In this method, specific gases are introduced into the furnace to create the required atmosphere for sintering the ceramic components. Depending on the material, different atmospheres such as oxygen, hydrogen, nitrogen, or argon may be used.

-

-

In recent years, carbon-plated running shoes have rapidly risen to prominence in the marathon community, becoming a favorite among many runners. The widespread appeal of these shoes lies in their use of supercritical foam materials for the midsole, which offer exceptional lightweight properties and superior cushioning with rebound performance. Additionally, the carbon plate reinforces the midsole structure, providing arch support and stability, enhancing energy return, and delivering powerful propulsion.

The Importance of Running Shoes in Marathon Sports

In the footwear industry, marathon running has become one of the most popular activities. As a high-intensity sport, marathon running places extremely high demands on the performance of running shoes. Research shows that under specific running conditions, every additional 100g in shoe weight increases the running time for a 3000m distance by 0.78%. Therefore, a lightweight and comfortable running shoe is crucial for enhancing running efficiency.

During a marathon, prolonged running often leads to a decline in energy and reduced muscle control, resulting in decreased joint and muscle stability. This can cause energy transfer inefficiencies during running, leading to energy loss. After long-distance running, significant changes in foot morphology are observed, such as excessive inward rotation of the ankle and a tendency for the arch to lower. If running shoes fail to provide adequate support and timely cushioning, these changes may trigger various sports injuries.

For instance, functional or non-functional overtraining can result in a series of syndromes. When external loads exceed the tissue's recovery capacity and rapid recovery is not achieved, it may lead to tissue overload injuries. To mitigate energy loss caused by inefficient energy transfer and alleviate fatigue from marathon running, it is essential to incorporate sufficient support and cushioning mechanisms, particularly in the shoe sole, to promote foot function recovery throughout the shoe's design.

Two Core Factors of Carbon-Plated Running Shoes: Both Are Indispensable

1. Carbon Plate

The carbon plate is a high-strength, lightweight carbon fiber composite material, typically made by combining carbon fiber strands with epoxy resin. It is usually embedded in the midsole of running shoes. Its primary function is to utilize the lever principle, storing the impact force generated when a runner lands and releasing it during the push-off phase, thereby creating additional propulsion.

Carbon plate technology can reduce energy loss with each step for runners, helping maintain running efficiency, especially during long-duration exercise. Research shows that running shoes with embedded carbon fiber plates can reduce running energy consumption by about 4%, making them regarded as "cutting-edge technology" for improving performance. Carbon plate running shoes can be divided into three types: "support type," "stabilizing type," and "propulsion type."

Support Type: These shoes typically have a small carbon plate area, or the area of focus is around the arch. The carbon plate absorbs a significant amount of downward force on the arch, providing arch support and reducing pressure on it.

Stabilizing Type: These shoes are developed based on the "support type," with a larger carbon plate area. The carbon plate typically forms an "X" or "Y" shape in the center of the shoe, extending forward and backward. The primary function is to provide "support" and "stability."

Propulsion Type (Shovel Type): These shoes have a whole piece of carbon plate design, without perforation, offering the well-known benefit of "performance enhancement" associated with carbon plate shoes.

Despite the many advantages of carbon plate running shoes, they are not suitable for all runners. The rigidity and structural characteristics of the carbon plate make them more suitable for runners with strong running techniques and power. If a runner lacks sufficient strength and technique, they may feel discomfort or increase the risk of injury. Runners with different needs should choose the appropriate type of carbon plate:

- Support Type: Best for high-mileage training, providing additional arch support and stability.

- Stabilizing Type: Suitable for intermediate-level competitive runners, helping to better utilize the carbon plate's performance to improve running economy.

- Propulsion Type: Specifically designed for performance-focused runners, maximizing the propulsion effect to increase speed.

Of course, it is important to objectively recognize that while carbon plates are powerful, in running shoes, they need to be paired with high-performance foam midsoles to achieve their full potential. The two complement each other. The carbon plate is generally placed above, below, or embedded within the midsole.

2. Midsole Technology

2.1 PEBA

In recent years, PEBA (polyether block amide) elastomer has gradually become one of the most powerful materials for running shoe midsoles. It is a block copolymer made from rigid polyamide segments and soft polyether segments. The combination of the rigidity of polyamide and the elasticity of polyether allows the PEBA elastomer to achieve extremely high energy recovery during repeated bending, thus reducing energy loss to a very low level.

Nike's ZoomX midsole technology is made from PEBAX supercritical foam and boasts an energy return rate of up to 85%. This innovation has caused a huge sensation in the running shoe industry and is considered one of the top midsole materials. Running shoes equipped with ZoomX, such as the Alphafly and Vaporfly series, have become the go-to footwear for long-distance running legends like Eliud Kipchoge and Haile Gebrselassie.

2.2 EVA

EVA (Ethylene Vinyl Acetate) is one of the earliest foam materials used in shoe midsoles. It is lightweight, easy to process, and the rebound rate of pure EVA foam generally ranges from 40% to 45%. Due to its cost advantage, EVA foam material has been the primary material choice for mainstream sports shoes for a long time.

2.3 ETPU

ETPU (Expanded Thermoplastic Polyurethane) is a type of thermoplastic elastomer made from a block copolymer consisting of diisocyanates, chain extenders, and polyols. The soft segments made from polyols exhibit flexibility and toughness, while the diisocyanates act as hard segments, providing hardness and rigidity. After crystallizing, the hard segments form physical crosslinking points, which gives TPU its high elasticity. Therefore, TPU has notable advantages such as high tensile strength, large elongation, and low permanent deformation under long-term compression.

When TPU is foamed, it becomes ETPU, which has a popcorn-like texture and exhibits excellent rebound and deformation recovery abilities. The ball rebound value of its foam is typically as high as 60%. In 2013, Adidas introduced the Boost midsole technology, centered around "popcorn" (ETPU), and used it in the EnergyBOOST running shoe. In 2015, Adidas launched the UltraBoost midsole foam technology and the UltraBoost series running shoes, which created a huge sensation in the running shoe industry. In July of this year, Adidas launched the latest Ultraboost 5 and Ultraboost 5X, with the Ultraboost 5 midsole featuring Adidas' latest LIGHT BOOST technology, which reduces weight while providing all the advantages of standard BOOST foam.

2.4 TPEE

TPEE (Thermoplastic Polyester Elastomer) is essentially a block copolymer made from polyester as the hard segment and polyether/polyester as the soft segment. The most common type of TPEE is the polyether ester type, with PBT (Polybutylene Terephthalate) and PTMG (PolyTetraHydroFuran Glycol) as the main structural components.

The high rebound elasticity, fatigue resistance, and low-temperature flexibility of TPEE make it an ideal material for outdoor sports products. In early 2022, Adidas launched the Adizero ADIOS Pro 2, equipped with its Lightstrike Pro technology. This material is made from TPEE supercritical foam, offering a cushioning and rebound experience comparable to ZoomX, and it achieved excellent results in the ROAD TO RECORDS challenge.

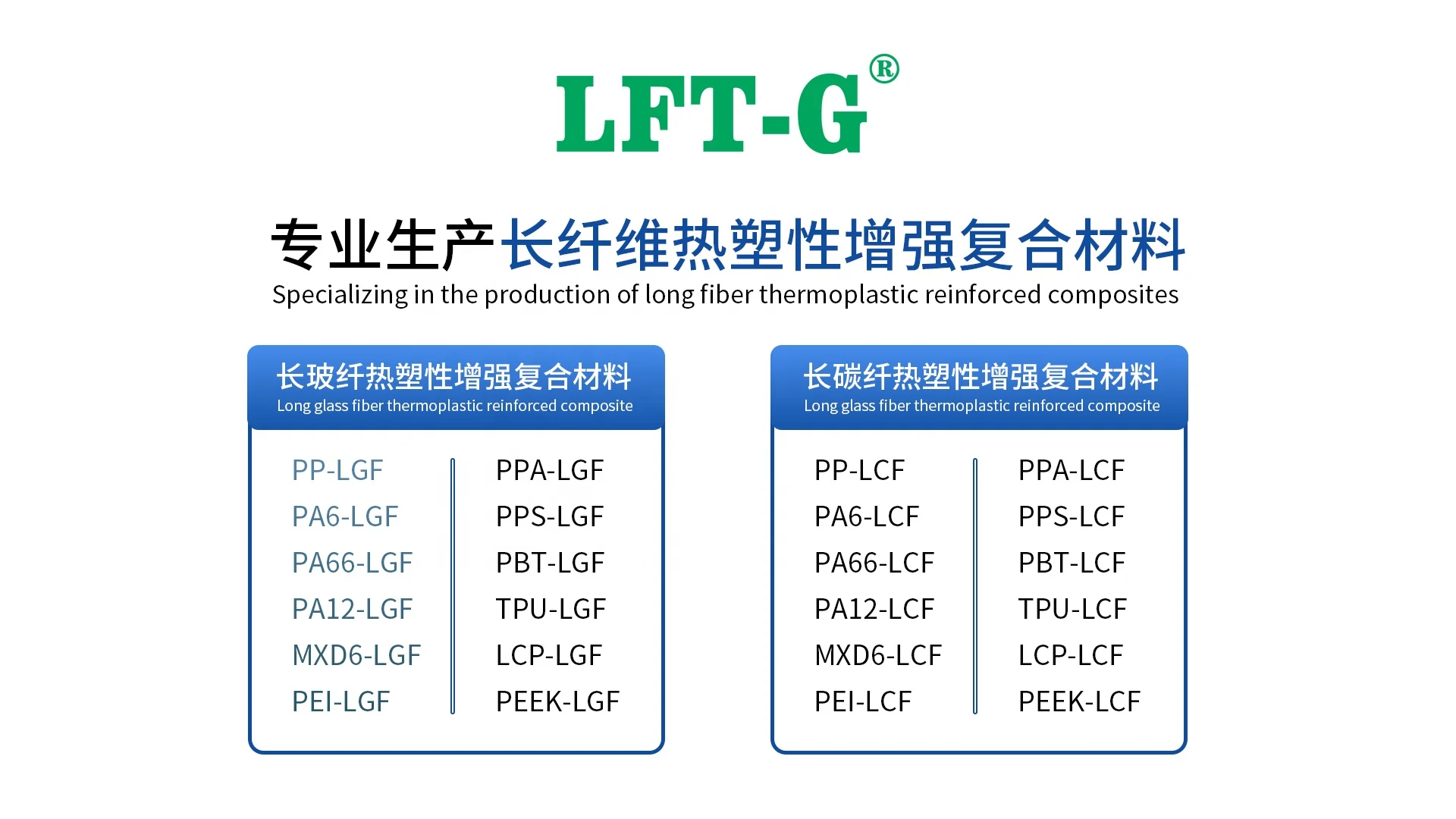

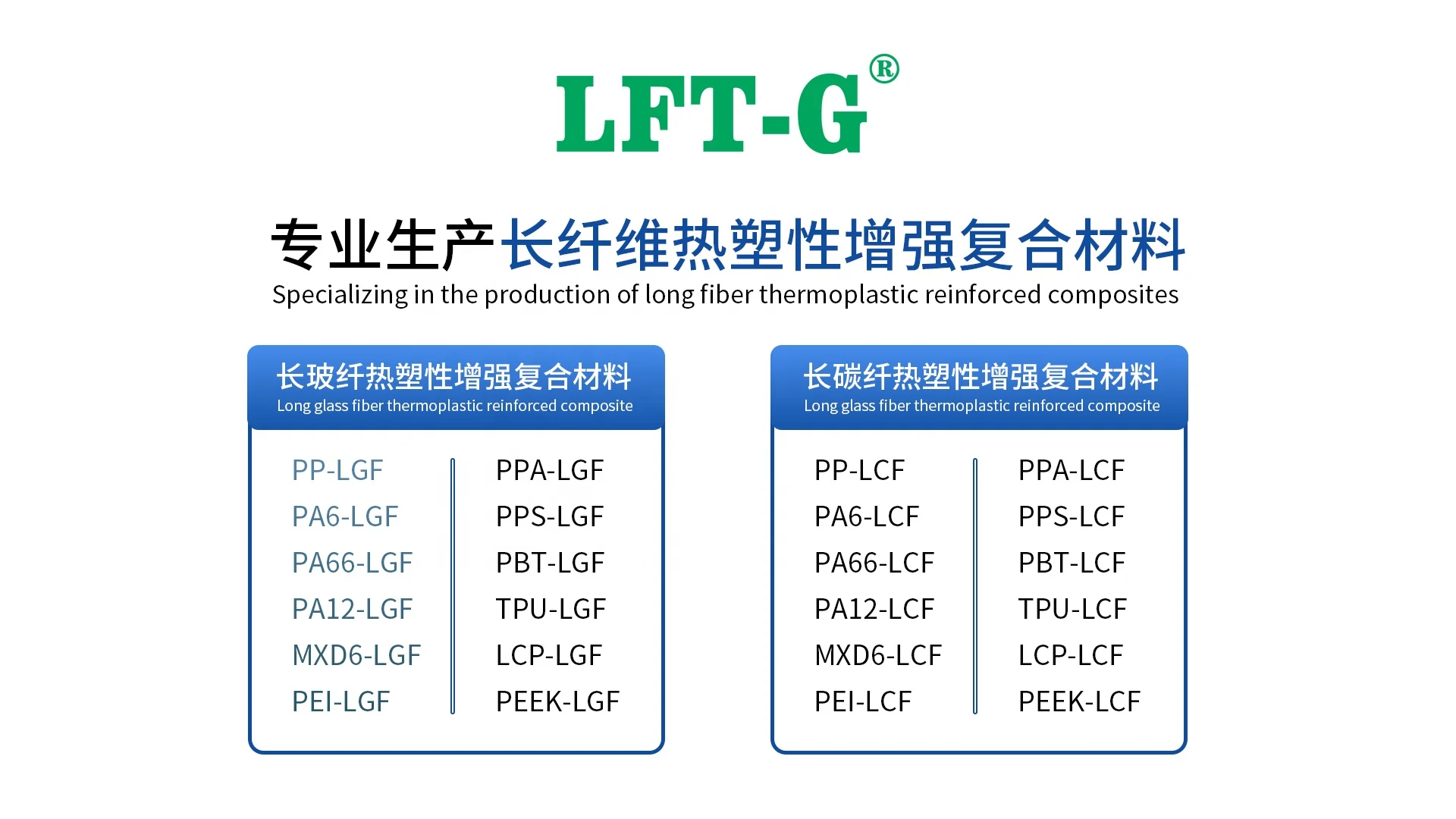

Xiamen LFT offers a variety of carbon fiber composites for carbon plate production in shoe soles.

You can contact us to receive free technical support.

To improve the hydrolysis degree of polyacrylamide (PAM), you can consider the following methods:

1. Increase the reaction time: Hydrolysis of PAM is typically carried out by treating it with a base, such as sodium hydroxide (NaOH), at an elevated temperature. By extending the reaction time, you allow more time for the hydrolysis reaction to occur, leading to a higher degree of hydrolysis.

2. Increase the reaction temperature: Higher temperatures generally facilitate chemical reactions. Increasing the temperature during the hydrolysis process can accelerate the reaction rate and enhance the hydrolysis degree. However, be cautious not to exceed the temperature limits to avoid degradation or undesirable side reactions.

3. Adjust the pH: The hydrolysis reaction of PAM is sensitive to the pH of the solution. Increasing the pH by adding more base, such as NaOH, can promote the hydrolysis process. However, excessive pH values can result in PAM degradation. It is important to optimize the pH conditions for the desired hydrolysis degree.

4. Increase the concentration of the base: The hydrolysis reaction of PAM is catalyzed by hydroxide ions (OH-). Therefore, by increasing the concentration of the base in the reaction mixture, you enhance the availability of hydroxide ions, which can lead to an increased hydrolysis degree. However, excessive base concentration should be avoided to prevent unwanted side reactions or degradation.

5. Use a catalyst: Certain catalysts can be employed to assist in the hydrolysis reaction of PAM, accelerating the process and increasing the hydrolysis degree. These catalysts can include transition metals or specific enzymes. This method requires careful selection and optimization of the catalyst for the particular hydrolysis reaction.

6. Utilize microwaves or ultrasound: Applying microwave or ultrasound irradiation during the hydrolysis process can provide additional energy to the reaction system, promoting the hydrolysis reaction and increasing the hydrolysis degree. These techniques can enhance the reaction rate and efficiency, thereby improving the hydrolysis of PAM.

It's worth noting that the hydrolysis degree of PAM might have significant implications for its desired application. Therefore, it's crucial to optimize the hydrolysis conditions based on the specific requirements and intended use of the hydrolyzed PAM product.

PVA dustless chalk erasers is a new type of product that first appeared in the 1990s. It is made of polyvinyl alcohol as raw material and produced through a special process. PVA, also known as Polyvinyl alcohol, is a synthetic polymer derived from renewable resources, making it an eco-friendly choice for various applications. With its excellent biodegradability and non-toxic nature, PVA is recognized as a sustainable alternative to traditional materials. Incorporating PVA into classroom equipment, such as dustless chalk erasers, presents numerous advantages to both teachers and students.

In a direct comparison between PVA dustless chalk erasers and traditional chalk erasers, the advantages of PVA become evident. While traditional erasers generate significant dust, PVA erasers eliminate this concern, reducing the risk of chalk-related allergies and promoting cleaner air quality. Additionally, PVA erasers offer improved erasing efficiency and lifespan, requiring less frequent replacement and resulting in cost savings for educational institutions.

The key to achieving dust-free wiping lies in its unique internal structure and cleaning mechanism. Although its appearance is similar to a traditional blackboard eraser, its internal structure is quite different. The interior of the dust-free blackboard eraser uses an efficient adsorption material that combines ultrafine PVA fiber and high adsorbent. This material can quickly absorb dust into the interior when wiping to avoid dust. The fine structure of microfiber not only enhances the adsorption force, but also ensures a good cleaning effect.

PVA dust-free blackboard brings people a cleaner and healthier working and learning environment. It plays an important role in the field of education and other fields and has become an integral part of people's lives. The success of PVA dustless blackboard erasers also inspires us to pay more attention to environmental protection in social development, and pay more attention to people's health and quality of life in product design and use.

Website: www.elephchem.com

Whatsapp: (+)86 13851435272

E-mail: admin@elephchem.com

ElephChem Holding Limited, professional market expert in Polyvinyl Alcohol(PVA) and Vinyl Acetate–ethylene Copolymer Emulsion(VAE) with strong recognition and excellent plant facilities of international standards.