Polyvinyl Alcohol PVA serves as an excellent adhesive for paints and coatings due to its strong bonding capabilities. It provides secure adhesion on various surfaces, including wood, metal, and plastics. Additionally, PVA glue offers good resistance to water, offering durability and longevity to the finished product. Specific like PVA 24-88 The paper making industry heavily relies on PVA adhesive for its superior binding properties. PVA plays a crucial role in paper formation, providing excellent adhesion between fibers. PVA adhesive enhances paper strength, improves printability, and reduces paper breakage during processing. For instance, like PVA 17-88 PVA adhesive finds extensive application in the woodworking industry, offering secure bonding for wood joints and assemblies. It provides strong adhesion with the ability to fill gaps and provide structural integrity to woodwork projects. Such as PVA 26-88 In the textile industry, PVA plays a vital role in various applications, including fabric sizing, finishing, and bonding. PVA adhesive provides a strong bond between different types of fabrics, enhancing the fabric's stability and durability. It is often used in textile printing, laminating, and embroidery applications due to its excellent film-forming properties. PVA adhesive ensures that textile products withstand repeated washing and retain their shape and color. One significant advantage of PVA is its water-soluble nature. This feature makes it convenient for various applications, including adhesives, films, and packaging. PVA's water solubility allows for easy cleanup and is particularly crucial in applications that require temporary adhesion or easy removal. It also makes PVA a preferred choice for water-soluble packaging materials. For example, pharmaceutical grade PVA0588 can be used to produce pharmaceutical capsule coatings. In addition to some of the applications mentioned above, PVA is also used in other industries. For example, PVA 20-88

Unveiling the Versatility and Applications of PVA

Why is Polyvinyl Alcohol in-demand across different industries?

Polyvinyl Alcohol (PVA One of the key reasons for the widespread use of Polyvinyl Alcohol is its excellent water-solubility. When dissolved in water, PVA forms a clear, transparent, and flexible film that exhibits strong adhesion to different surfaces. This property makes it invaluable in applications such as paper coatings, adhesives, and textile sizing. Polyvinyl Alcohol is often preferred due to its compatibility with a wide range of materials. It exhibits excellent adhesion to various substrates such as paper, textiles, metal, wood, and plastics. This versatility allows for its use in multiple industries, including packaging, construction, textiles, and ceramics.

Introduction to different nonwoven fabric topsheet of diapers

Spunbond nonwoven fabric, hot air nonwoven fabric and thermal bond nonwoven fabric can all be used as the topsheet materials of diapers, and they each have different advantages and disadvantages. The following is a detailed analysis of these three materials:

Advantages: Spunbond nonwoven fabric has high strength, good elongation at break and tear strength, which makes diapers less likely to break during use. Spunbond nonwoven fabric is relatively thin, which helps to reduce the overall weight of diapers and improve the comfort of wearing.

Disadvantages: Compared with hot air nonwoven fabric, spunbond nonwoven fabric is slightly inferior in softness and breathability, which may cause a certain friction to the baby's delicate skin and affect breathability.

Advantages: Hot air nonwoven fabric has high fluffiness and elasticity, which makes the surface of diapers fit the baby's skin better and provide better comfort and wrapping. Hot air non-woven fabrics are soft to the touch and will not cause excessive friction on the baby's skin. At the same time, they have good warmth retention and are suitable for use in colder environments. Hot air non-woven fabrics have good air permeability and water permeability, which helps keep the inside of the diaper dry and reduce the risk of red bottom.

Disadvantages:

Low strength and easy deformation: The strength of hot air non-woven fabrics is relatively low and it is easy to deform during pulling, so more frequent changes may be required to maintain the integrity of the diaper.

3. Thermal bond non woven fabric

Advantages: The production process of thermal bond non woven fabric is relatively mature and the cost is low, so the price is relatively affordable.

Disadvantages: Hard feel and average breathability: Compared with hot air non-woven fabrics, thermal bond non woven fabric may feel slightly harder and have average breathability, which may not be suitable for babies with high comfort requirements.

(Note: Thermal bond non woven fabric is relatively rarely used on the topsheet of baby diapers, and are more commonly used in the medical and health fields. The reason for mentioning them here is to provide comprehensive information.)

Summary: When choosing the surface material of diapers, you need to consider factors such as the baby's skin condition, activity level, and seasonal changes. If the baby has delicate skin and requires high comfort, you can choose hot-air non-woven fabrics as the surface of diapers; if the baby has a large amount of activity and needs stronger mechanical support, you can choose spunbond non-woven fabrics as the surface of diapers. At the same time, you also need to pay attention to the frequency of diaper changes and cleaning care to keep the baby's skin healthy and comfortable.

What raw materials can be used for sanitary napkin topsheet materials?

Sanitary napkin topsheet materials can use a variety of raw materials, the following are some common ones:

Dry mesh material: The surface of this sanitary pad is made of polyethylene (PE) film with small holes, also known as perforated film. It has the advantages of fast absorption and long-lasting dry surface. However, because it is a chemical fiber component, it may cause allergic reactions such as itching, redness and swelling for women with sensitive skin.

Cotton surface material: The cotton surface is not pure cotton, but is made of non-woven fabrics such as polypropylene (PP). This material is soft and can give people a touch similar to pure cotton, but it has poor breathability and may make private parts feel stuffy during use. In addition, bleaching may be required during the production process, so most cotton surface sanitary napkins contain additives, but the allergenicity is relatively low.

Pure cotton surface material: The pure cotton surface is made of natural cotton fibers interwoven into a uniform, thin and soft non-woven fabric. This material is soft and comfortable, with minimal irritation to the skin, and is suitable for most women. Compared with chemical fiber materials, pure cotton sanitary napkins are more skin-friendly and can reduce allergies. However, pure cotton products tend to turn yellow over time, and are prone to breeding bacteria and mites at a certain temperature of the human body.

In addition to the above materials, some sanitary napkins use high-quality non-woven materials such as hot air non-woven fabrics as the surface layer. These materials are soft, breathable, and not easy to irritate the skin.

In general, the choice of sanitary napkin making raw materials depends mainly on personal skin conditions, needs, and budget. For women with sensitive skin, it is recommended to choose sanitary napkins made of natural materials such as pure cotton, silk or bamboo fiber; and for women who pursue a dry experience, dry mesh sanitary napkins may be a good choice.

The role of sanitary napkin adhesive

The position adhesive of sanitary napkins is a layer of adhesive medium that connects sanitary napkins to underwear. Its main functions are reflected in the following aspects:

Fixation: The main function of the position adhesive is to firmly stick the sanitary napkins to the underwear to prevent displacement during use, and ensure that women can keep the sanitary napkins in a stable position during activities, exercise or sleep, thereby avoiding embarrassment and discomfort.

No residue and easy to tear off: The position adhesive of sanitary napkins with excellent performance can be easily separated from the underwear when torn off, without leaving any glue residue, protecting the cleanliness and integrity of the underwear. At the same time, the peel strength of the position adhesive is moderate, and it will not fall off easily due to being too weak, nor will it be difficult to tear off or tear the back film due to being too strong.

Adaptability and flexibility: High-quality sanitary napkin position adhesive can adapt to underwear fabrics of different materials, weaving methods and surface treatments, and meet the complex fabric morphology, style and elongation requirements. In addition, the position glue must also have good anti-transfer properties to ensure that it will not be transferred to the underwear due to friction during use.

Safety and comfort: The sanitary napkin position adhesive is usually made of safe and non-toxic materials, which is skin-friendly and non-irritating. Its soft and flexible characteristics can match women's daily activities, ensuring comfort and peace of mind.

In summary, the position adhesive of sanitary napkins plays a vital role in sanitary napkin products. It is not only related to the stability and use effect of the product, but also directly affects the comfort and satisfaction of consumers. Therefore, when choosing sanitary napkins, consumers should pay attention to the performance and quality of the adhesive backing to ensure the best use experience.

Why do wet wipes use spunlace nonwovens?

The reason why wet wipes use spunlace nonwovens is mainly based on the following reasons:

High water absorbency: Spunlace nonwovens can quickly absorb water and liquids, keep the wetness of wet wipes, thereby extending the use time of wet wipes, while ensuring that the surface is dry after wiping. This feature is crucial in products such as wet wipes that require high water absorbency.

Softness and comfort: Spunlace nonwovens have a soft and delicate touch, suitable for direct contact with the skin, and will not cause friction or discomfort to the user. This is especially important for wet wipes products that need to be wiped frequently or contact the skin for a long time.

Strength and durability: Spunlace nonwovens are reinforced by high-pressure micro-water jets, have high strength, and can resist tearing and abrasion. This makes wet wipes less likely to break during use and improves the durability of the product.

Breathability: Spunlace nonwovens have good breathability, which helps to maintain ventilation and air circulation in the wiped area, reduce humidity and stuffiness, and improve comfort.

Environmental protection: Spunlace nonwovens are usually degradable, which is in line with the trend of sustainable development and environmental protection. As consumers pay more and more attention to environmental issues, wet wipes products made of environmentally friendly materials are more popular.

Versatility: Spunlace nonwovens can be customized according to specific needs, such as patterns, colors, sizes and water absorption capacity, to meet the diverse needs of wet wipes products.

In summary, the use of spunlace nonwovens in wet wipes is based on a comprehensive consideration of its high water absorption, softness and comfort, strength and durability, breathability, environmental protection and versatility. These characteristics make spunlace nonwovens an ideal choice for wet wipes products.

Composite Material Introduction

There are many choices for raw materials of composite materials, including resin, fiber and core material, and each material has its own unique properties such as strength, stiffness, toughness and thermal stability, and the cost and output are also different. However, the final performance of composite materials is not only related to the resin matrix and fiber (and the core material in the sandwich structure), but also closely related to the design method and manufacturing process of the materials in the structure.

Ten common composite molding processes

1. Spraying: A molding process in which the chopped fiber reinforcement material and the resin system are sprayed into the mold at the same time and then cured under normal pressure to form a thermosetting composite product.

Typical applications: simple fences, low-load structural panels, such as convertible bodies, truck fairings, bathtubs and small boats.

2. Hand lay-up: The resin is manually impregnated into the fibers, which can be woven, braided, stitched or bonded. Hand lay-up is usually done with a roller or brush, and then the resin is squeezed into the fibers with a glue roller. The laminate is cured under normal pressure.

Typical applications: standard wind turbine blades, mass-produced boats, architectural models.

3. Vacuum bag process: The vacuum bag process is an extension of the above-mentioned hand lay-up process, that is, a layer of plastic film is sealed on the mold to evacuate the hand-laid laminate, and an atmospheric pressure is applied to the laminate to achieve the effect of exhaust and compaction to improve the quality of the composite material.

Typical applications: large-sized yachts, racing car parts, and bonding of core materials during shipbuilding.

4. Winding: Winding is basically used to manufacture hollow, round or oval structures such as pipes and troughs. The fiber bundle is impregnated with resin and wound on the mandrel in various directions. The process is controlled by the winding machine and the mandrel speed.

Typical applications: chemical storage tanks and delivery pipes, cylinders, firefighter breathing tanks.

5. Pultrusion: The fiber bundle drawn from the spool rack is dipped in resin and passed through a heating plate, where the resin is impregnated into the fiber and the resin content is controlled, and the material is finally cured into the required shape; this fixed shape cured product is mechanically cut into different lengths. The fiber can also enter the hot plate in a direction other than 0 degrees. Pultrusion is a continuous production process, and the cross-section of the product usually has a fixed shape, allowing for slight changes. The pre-impregnated material that passes through the hot plate is fixed and laid into the mold for immediate curing. Although the continuity of this process is poor, the cross-sectional shape can be changed.

Typical applications: beams and trusses of house structures, bridges, ladders and fences.

6. Resin transfer molding process: Dry fibers are spread in the lower mold, and pressure can be applied in advance to make the fibers fit the mold shape as much as possible and bonded; then, the upper mold is fixed to the lower mold to form a cavity, and then the resin is injected into the cavity. Usually, vacuum-assisted resin injection and fiber impregnation are used, namely vacuum-assisted resin injection (VARI). Once the fiber impregnation is completed, the resin introduction valve is closed, and the composite material is cured. Resin injection and curing can be performed at room temperature or under heating conditions.

Typical applications: small and complex space shuttle and automotive parts, train seats.

7. Other infusion processes: Lay the dry fiber in a similar way to the RTM process, and then lay the peeling cloth and guide net. After the layering is completed, it is completely sealed with a vacuum bag. When the vacuum degree reaches a certain requirement, the resin is introduced into the entire layer structure. The distribution of the resin in the laminate is achieved by guiding the resin flow through the guide net, and finally the dry fiber is completely impregnated from top to bottom.

Typical applications: trial production of small boats, train and truck body panels, wind turbine blades.

8. Prepreg-Autoclave Process: The fiber or fiber cloth is pre-impregnated with a resin containing a catalyst by the material manufacturer, and the manufacturing method is high temperature and high pressure method or solvent dissolution method. The catalyst is latent at room temperature, which makes the material effective for several weeks or months at room temperature. Refrigerated conditions can extend its shelf life. The prepreg can be laid into the mold surface by hand or machine, and then covered with a vacuum bag and heated to 120-180°C. After heating, the resin can flow again and finally solidify. The material can be subjected to additional pressure in an autoclave, usually up to 5 atmospheres.

Typical applications: Space shuttle structures (such as wings and tails), Formula 1 racing cars.

9. Prepreg - Non-autoclave process: The manufacturing process of low temperature curing prepreg is exactly the same as that of autoclave prepreg, except that the chemical properties of the resin allow it to be cured at 60-120°C. For low temperature 60°C curing, the working time of the material is only one week; for high temperature catalyst (>80°C), the working time can reach several months. The fluidity of the resin system allows the use of vacuum bag curing only, avoiding the use of autoclaves.

Typical applications: high performance wind turbine blades, large racing boats and yachts, rescue aircraft, train components.

10. Semi-preg SPRINT/beam prepreg SparPreg non-autoclave process: It is difficult to remove bubbles between layers or overlapping layers during the curing process when using prepreg in thicker structures (>3mm). To overcome this difficulty, pre-vacuuming was introduced into the lamination process, but it significantly increased the process time. Semi-preg SPRINT consists of a sandwich structure with two layers of dry fibers and a layer of resin film. After the material is laid into the mold, the vacuum pump can completely drain the air in it before the resin heats up and softens and wets the fibers and then cures. Beam prepreg SparPreg is an improved prepreg that can easily remove bubbles from between the two bonded layers of material when cured under vacuum conditions.

Typical applications: high-performance wind turbine blades, large racing boats and yachts, rescue aircraft.

Our company Nanjing Yolatech can produce a variety of epoxy resins for composite materials. Pls feel free to contact for ir. We will serve you wholeheartedly!

Epoxy Resin for High Performance Electronic Packaging Materials

Background

Electronic packaging glue is used to package electronic devices. It is a type of electronic glue or adhesive that performs sealing, encapsulation or potting. After being packaged with electronic packaging glue, it can play the role of waterproof, moisture-proof, shockproof, dustproof, corrosion-resistant, heat dissipation, confidentiality, etc. Therefore, electronic packaging glue needs to have the characteristics of high and low temperature resistance, high dielectric strength, good insulation, and environmental safety.

Why choose epoxy resin?

With the continuous development of large-scale integrated circuits and the miniaturization of electronic components, the heat dissipation of electronic components has become a key issue affecting their service life. There is an urgent need for high thermal conductivity adhesives with good heat dissipation performance as packaging materials.

Epoxy resin has excellent heat resistance, electrical insulation, adhesion, dielectric properties, mechanical properties, small shrinkage, chemical resistance, and good processability and operability after adding curing agent. Therefore, currently, many semiconductor devices abroad are encapsulated with epoxy resin.

The development of epoxy resin

With the increasing calls for environmental protection and the increasing performance requirements of the integrated circuit industry for electronic packaging materials, higher requirements have been put forward for epoxy resins. In addition to high purity, low stress, thermal shock resistance and low water absorption are also issues that need to be solved urgently.

In response to problems such as high temperature resistance and low water absorption, domestic and foreign research has started from molecular structure design, focusing mainly on blending modification and the synthesis of new epoxy resins. On the one hand, biphenyl, naphthalene, sulfone and other groups and fluorine elements are introduced into the epoxy skeleton to improve the moisture and heat resistance of the material after curing. On the other hand, by adding several types of representative curing agents, the curing kinetics, glass transition temperature, thermal decomposition temperature and water absorption of the cured product are studied, in an effort to prepare high-performance epoxy resins for electronic packaging materials.

Introduction of several special epoxy resins for electronic packaging

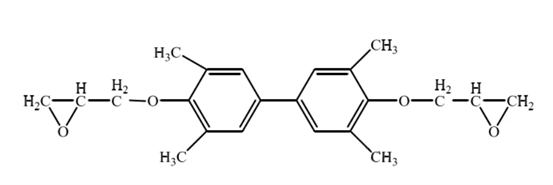

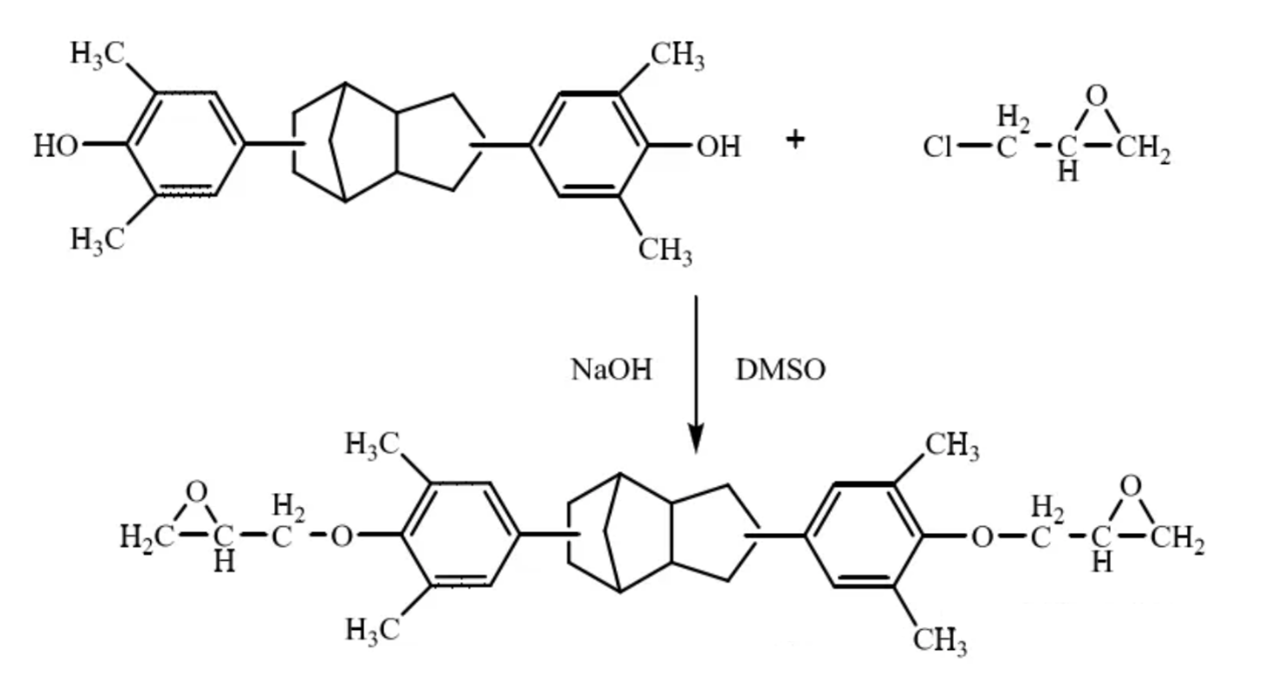

1. Biphenyl type epoxy resin

The tetramethyl biphenyl diphenol epoxy resin (its structure is shown in the figure) synthesized by the two-step method exhibits high heat resistance, good mechanical properties and low water absorption after being cured by DDM and DDS. The introduction of the biphenyl structure greatly improves the heat resistance and moisture resistance, which is conducive to its application in the field of electronic packaging materials.

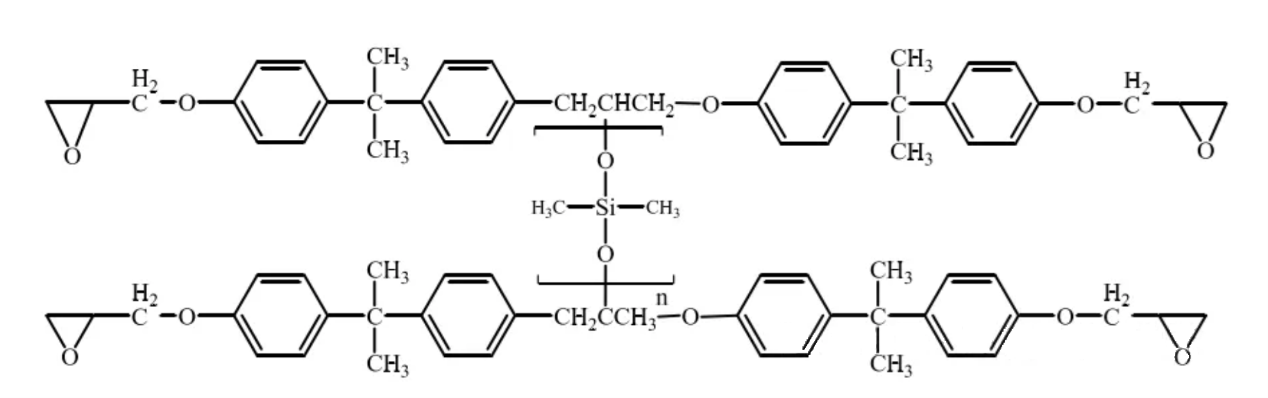

2. Silicone epoxy resin

Another research hotspot in the field of electronic packaging is the introduction of silicone segments, which can not only improve heat resistance, but also enhance toughness after epoxy curing. Silicon-containing polymers have good flame retardant properties. The low surface energy of silicon-containing groups causes them to migrate to the resin surface to form a heat-resistant protective layer, thereby avoiding further thermal degradation of the polymer.

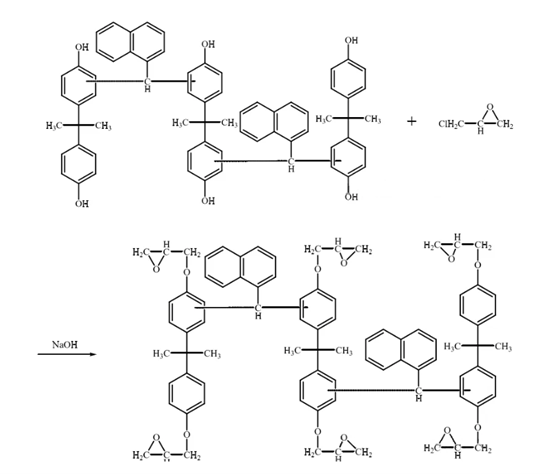

Some researchers have used chlorine-terminated organosiloxane polymers to modify bisphenol A epoxy resins, generating Si-O bonds through the reaction of terminal chlorine with the hydroxyl groups on the epoxy chain. The structural formula is shown in the figure below.

This method increases the cross-linking density of the cured resin without consuming epoxy groups, which not only toughens the resin but also improves its heat resistance and impact resistance.

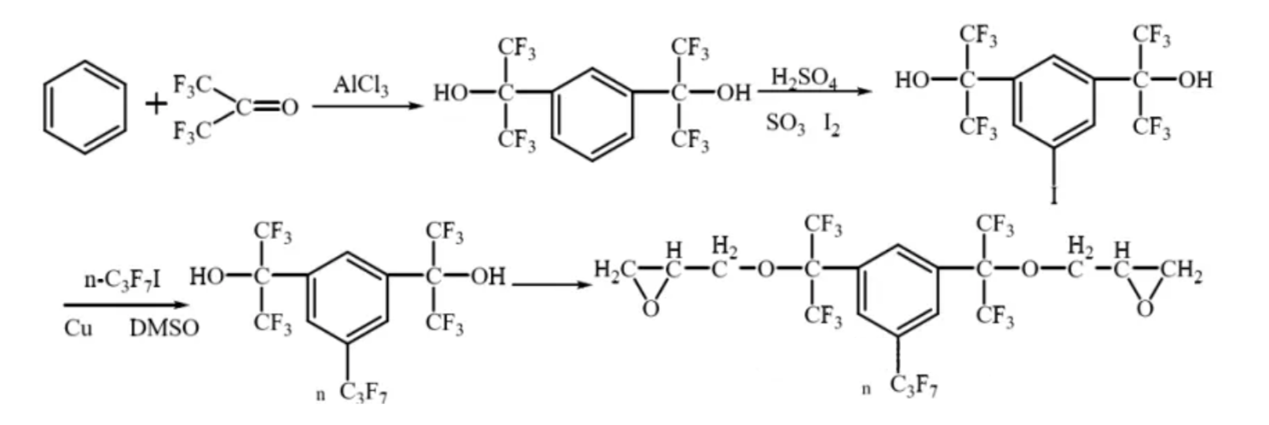

3. Fluorinated epoxy resin

Fluorine-containing polymers have many unique properties. Fluorine has the greatest electronegativity, the interaction between electrons and nuclei is strong, the bond energy between chemical bonds with other atoms is large, and the refractive index is low. Fluorine-containing polymers have excellent heat resistance, oxidation resistance and chemical resistance.

Fluorinated epoxy resin has the properties of dustproof and self-cleaning, heat resistance, wear resistance, corrosion resistance, etc. It can also improve the solubility of epoxy resin. At the same time, it has excellent flame retardancy, becoming a new material in the field of electronic packaging.

The fluorinated epoxy resin synthesized in the laboratory is liquid at room temperature and has extremely low surface tension. After curing with silanamine at room temperature or fluorine anhydride, an epoxy resin with excellent strength, durability, low surface activity, high Tg and high ultimate stability can be obtained. The synthesis steps are:

4. Containing dicyclopentadiene epoxy resin

Dicyclopentadiene o-cresol resin can be synthesized by reaction, the reaction formula is shown in the figure below. The resin is cured with methyl hexahydrophthalic anhydride and polyamide curing agent, and the Tg of the cured product is 141°C and 168°C respectively.

There is a new type of low-dielectric dicyclopentadiene epoxy resin (see figure below) whose performance is comparable to that of commercial bisphenol A epoxy resin, with a 5% heat loss of more than 382°C, a glass transition temperature of 140-188°C, and a water absorption rate (100°C, 24h) of only 0.9-1.1%.

5. Naphthalene-containing epoxy resin

Some researchers have synthesized a new type of naphthalene-containing phenolic epoxy resin, the reaction formula of which is shown in the figure below. Its DDS cured product exhibits excellent heat resistance, with a Tg of 262°C and a 5% thermal weight loss of 376°C.

Synthesis of Bisphenol A-Naphthaldehyde Novolac Epoxy Resin

6. Alicyclic Epoxy resin

The characteristics of alicyclic epoxy resins are: high purity, low viscosity, good operability, high heat resistance, small shrinkage, stable electrical properties and good weather resistance. They are particularly suitable for high-performance electronic packaging materials with low viscosity, high heat resistance, low water absorption and excellent electrical properties. They are extremely promising electronic packaging materials.

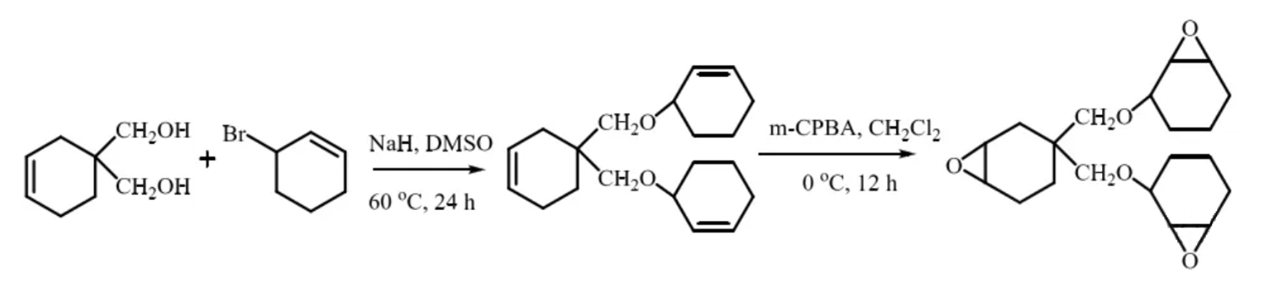

The figure below shows the reaction process of a new type of heat-resistant liquid alicyclic epoxy compound. It can be obtained by etherifying alicyclic olefin diols with halogenated hydrocarbons to form alicyclic triolefin ethers, which are then epoxidized.

7. Blending modified epoxy resin

Blending is an important method to effectively improve material properties. In an epoxy matrix, adding another or several epoxy resins can improve one or several specific properties of the matrix material, thereby obtaining a new material with better comprehensive performance. In epoxy molding compounds, blending can achieve the goal of reducing costs and improving performance and processing performance.

In future production research, in order to enable epoxy resins to be fully used in the domestic electronic packaging industry, improving the preparation process technology, exploring the curing system of high-performance epoxy resins resistant to moisture and heat and medium-temperature moisture and heat-resistant epoxy resins, and preparing new epoxy resin modified additives are the development directions of this research field.

Nanjing Yolatech provides all kinds of high purity and low chlorine epoxy resins and special epoxy resin, including Bisphenol A epoxy resin, Bisphenol F epoxy resin, Phenolic epoxy resin, Brominated epoxy resin, DOPO modified phenolic epoxy resin, MDI modified epoxy resin, DCPD epoxy resin, Multifunctional epoxy resin, Crystalline epoxy resin, HBPA epoxy resin and so on. And we also could provide all kinds of curing agents or hardeners and diluents for epoxy resin application. Welcome new and old customers to inquire, we will provide you with the best service.

How Can Polyvinyl Alcohol Enhance the Performance of Adhesive Products?

PVA For woodworkers, Polyvinyl Alcohol for Woodworking opens up new possibilities. Its water-soluble nature allows for easy application and cleanup, while providing a strong bond between wood surfaces. Whether it's joining pieces of furniture, laminating wooden panels, or creating intricate woodcraft, PVA-based adhesives ensure a reliable and long-lasting bond. In the paper-making industry, the demand for efficient and high-quality adhesive solutions is crucial. Polyvinyl Alcohol Glue for Paper Making offers excellent performance characteristics, boosting both the efficiency and quality of the production process. When applied as a coating on paper, PVA adhesive ensures improved strength, dimensional stability, and printability. Additionally, it provides excellent resistance to moisture, heat, and chemicals, enhancing the overall durability of paper products.