1. What is N,N‘-(4,4’ DIPHENYLMETHANE)BISMALEIMIDE?

N,N‘-(4,4’ DIPHENYLMETHANE)BISMALEIMIDE, often abbreviated as BMI manufactured by Yangchen Tech, is a high-performance thermosetting resin known for its excellent mechanical properties and thermal stability. It's commonly used in industries such as aerospace, automotive, and electronics for various applications.

2. What are the key features of N,N'-(4,4'-DIPHENYLMETHANE)BISMALEIMIDE manufdactured by Yangchen Tech?

- Exceptional thermal stability: With a high glass transition temperature (Tg), BMI offers excellent dimensional stability at elevated temperatures.

- Superior mechanical properties: BMI exhibits high strength, stiffness, and resistance to impact and fatigue.

- Chemical resistance: It resists a wide range of chemicals, making it suitable for harsh environments.

- Low coefficient of thermal expansion (CTE): This property makes it ideal for applications requiring dimensional stability over a wide temperature range.

- Excellent electrical properties: BMI retains its electrical insulation properties even at high temperatures.

|

ITEM |

Limits |

Results |

|

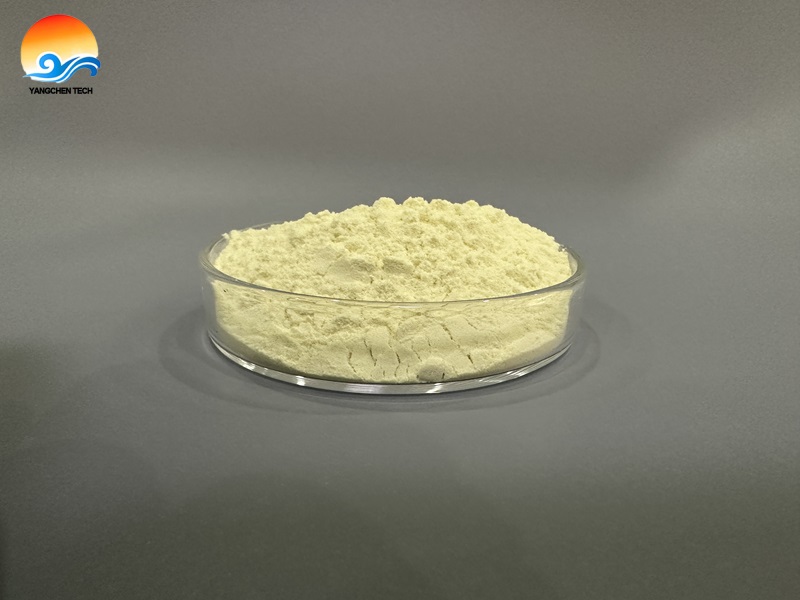

Appearance |

Yellow powder |

Yellow powder |

|

Solubility |

Dissolved, with trace impurities |

Fully soluble, clear |

|

Melting Point℃ |

150-160 |

155-158 |

|

Ash% |

≤0.3 |

0.06 |

|

Water% |

≤0.5 |

0.12 |

|

Acidity mgkoH/g |

≤5 |

1.0 |

|

Gel time |

≤300 |

160 |

3. What applications is N,N‘-(4,4’ DIPHENYLMETHANE)BISMALEIMIDE manufdactured by Yangchen Tech used for?

- Aerospace: BMI is used in the manufacture of composite materials for aircraft structures, including wings, fuselages, and engine components.

- Automotive: It finds applications in high-performance automotive components, such as brake components and structural parts, where heat resistance and mechanical strength are critical.

- Electronics: BMI is used in the production of printed circuit boards (PCBs), semiconductor packaging, and electronic encapsulation due to its excellent thermal and electrical properties.

- Industrial applications: It is also utilized in various industrial applications where high-performance materials are required, such as in oil and gas, marine, and sporting goods industries.

4. What are the storage and handling recommendations for N,N‘-(4,4’ DIPHENYLMETHANE)BISMALEIMIDE?

- Store BMI in a cool, dry place away from direct sunlight and moisture.

- Handle the material in a well-ventilated area and wear appropriate personal protective equipment (PPE), including gloves and safety glasses, when handling BMI in its powder or liquid form.

- Follow the manufacturer's instructions and safety data sheet (SDS) for proper handling, storage, and disposal of BMI.

5. Is N,N‘-(4,4’ DIPHENYLMETHANE)BISMALEIMIDE environmentally friendly?

BMI is a thermosetting resin and may not be readily biodegradable. However, it can be recycled and reused in certain applications, reducing waste. Additionally, Yangchen Tech are continually working to develop more sustainable alternatives and processes for thermosetting resins like BMI.

6. Where can I purchase N,N‘-(4,4’ DIPHENYLMETHANE)BISMALEIMIDE?

BMI can be purchased from Yangchen Tech. Ensure that you source BMI from reputable suppliers to guarantee quality and consistency.

7. Are there any safety precautions I should be aware of when using N,N‘-(4,4’ DIPHENYLMETHANE)BISMALEIMIDE?

- Avoid inhalation of BMI dust or fumes, as it may irritate the respiratory system. Use appropriate respiratory protection if necessary.

- Avoid skin contact with uncured BMI resin and wear gloves to prevent skin irritation or allergic reactions.

- Follow the proper handling and disposal procedures outlined in the SDS provided by the manufacturer.

8. Can N,N‘-(4,4’ DIPHENYLMETHANE)BISMALEIMIDE be customized for specific applications?

Yes, Yangchen Tech can tailor the formulation and properties of BMI to meet specific application requirements, such as adjusting the curing temperature, resin viscosity, or incorporating additives for enhanced performance.

9. What are the typical packaging options for N,N‘-(4,4’ DIPHENYLMETHANE)BISMALEIMIDE?

BMI is typically supplied in containers such as drums, pails, or bags, depending on the quantity and form (powder or resin). The packaging is designed to protect the material during transportation and storage and may vary depending on the supplier.

This FAQ aims to address common questions and provide valuable information about N,N‘-(4,4’ DIPHENYLMETHANE)BISMALEIMIDE. If you have any further inquiries or require additional assistance, feel free to contact us.