Styrene Maleic Anhydride Copolymer (SMA Copolymer) manufactured by Yangchen Tech is a highly versatile and widely used thermoplastic copolymer that combines the benefits of styrene and maleic anhydride. SMA is produced by copolymerizing styrene with maleic anhydride, resulting in a polymer that exhibits excellent chemical resistance, high thermal stability, and superior adhesion properties. Due to its unique properties, SMA has become an essential component in various industrial applications, particularly in plastics manufacturing.

Styrene Maleic Anhydride Copolymer produced by Yangchen Tech can help your products with strong bonding, high impact resistance, and enhanced durability,which can improve the performance of materials, especially in the plastic industry, makes it a go-to solution for manufacturers seeking to elevate the functionality of their products.

Basic Information

| Test Item |

Test Standards |

Test Data |

| Molecular weight and distribution |

GPC |

Mw=12~16*104.PDI=2.0~3.0 |

| Glass transition temperature/℃ |

DSC |

160~210℃(Adjustable) |

| Initial decomposition temperature/℃ |

TGA |

395-405℃ |

| Density |

ASTM-D792 |

1.00~1.15g/cm3 |

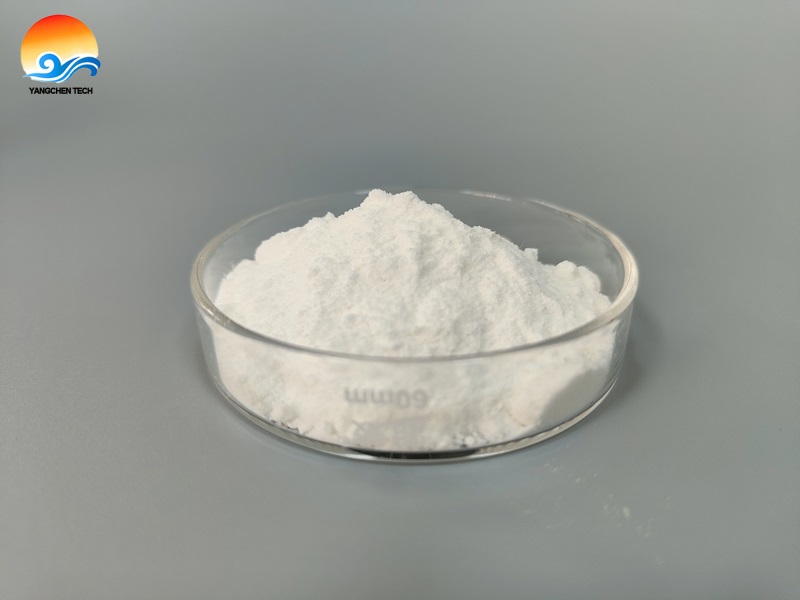

| Appearance |

NG |

Off-white powder |

Applications of Styrene Maleic Anhydride Copolymer in Plastics Manufacturing

1. Enhancing Impact Resistance in Plastics

SMA Copolymer plays a critical role in enhancing the impact resistance of plastic products. It is often used as a modifier in the production of engineering plastics, such as ABS (Acrylonitrile Butadiene Styrene) and polystyrene. When added to these materials, SMA copolymer significantly improves their strength and durability without compromising flexibility. This makes it an essential ingredient in producing products that need to withstand stress, impact, and high temperatures.

2. Adhesive and Coating Applications

The high reactivity of SMA makes it an excellent choice for adhesives and coatings. By combining SMA with other resins or polymers, manufacturers can create strong, durable bonding agents. This is particularly useful in industries where adhesive strength and resistance to environmental factors are critical. Whether it's in automotive applications, electronics, or packaging, SMA-based adhesives provide a reliable solution for manufacturers.

3. Plastic Alloying and Blending

SMA is widely used to enhance the properties of plastic alloys. It acts as a compatibilizer, helping to blend otherwise incompatible polymers. In plastics, SMA improves the overall processing capabilities and enhances mechanical properties, especially when combined with high-performance polymers like polycarbonate (PC), polyphenylene oxide (PPO), or polyphenylene sulfide (PPS). By creating a more homogenous blend, SMA improves the structural integrity of plastic parts used in demanding environments.

4. Applications in Automotive Plastics

The automotive industry relies heavily on advanced materials that offer durability, strength, and resistance to heat and wear. SMA Copolymer is often used in automotive applications such as interior trim, bumpers, and other plastic components. Its ability to improve impact resistance, along with its excellent thermal stability, makes it an ideal choice for manufacturing durable automotive parts that can withstand extreme conditions.

5. Medical Plastics and Devices

Styrene Maleic Anhydride Copolymer ’s high purity and biocompatibility make it suitable for use in medical devices and equipment. Its excellent chemical resistance ensures that medical plastics maintain their integrity when exposed to harsh cleaning agents or sterilization processes. Additionally, its strong bonding ability makes it ideal for creating medical products that require long-lasting durability.

Why Choose Styrene Maleic Anhydride Copolymer for Your Plastic Manufacturing Needs?

Enhanced Performance: SMA Copolymer boosts the performance of plastics by improving impact resistance, adhesion strength, and thermal stability.

Customization: It can be tailored for specific applications, offering flexibility in plastic product development.

Cost-Effectiveness: By improving material properties and enabling better processing techniques, SMA helps reduce manufacturing costs in the long run.

Sustainability:Styrene Maleic Anhydride Copolymer efficient bonding properties can lead to lighter and more durable plastic products, supporting sustainable manufacturing practices by reducing waste and material usage. Any questions,feel free to contact:business@xysjgm.com