When it comes to industrial pumping applications, finding the right pump to handle corrosive and abrasive materials is crucial. Two popular options in the market are corrosion-resistant pumps and wear-resistant pumps. In this blog post, we will compare and contrast these pumps to help you make an informed decision for your specific requirements.

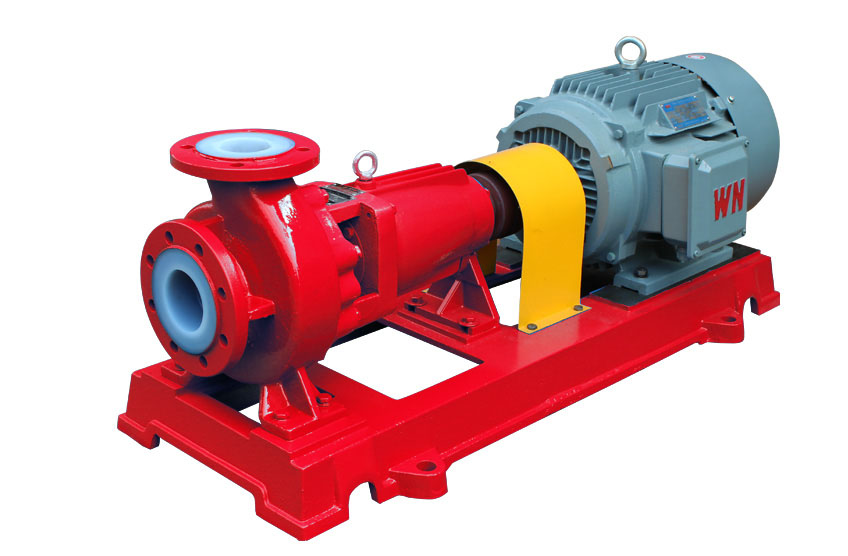

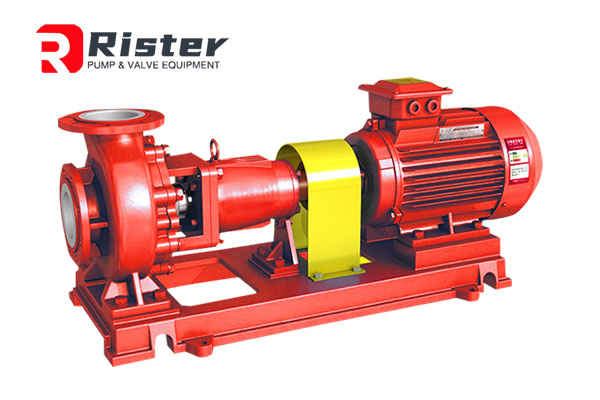

Corrosion-Resistant Pumps

Corrosion-resistant pumps are designed to withstand the damaging effects of corrosive fluids. These pumps are commonly used in industries such as chemical processing, mining, and wastewater treatment. They are typically constructed with materials like stainless steel, titanium, or other corrosion-resistant alloys. These pumps are specifically engineered to handle aggressive liquids that can deteriorate standard pumps over time.

One well-known manufacturer of corrosion-resistant pumps is [Slurry Pump Manufacturer]. They offer a range of pumps designed to resist chemical corrosion and provide superior performance in harsh environments. Their pumps are equipped with features like anti-corrosive coatings and special seal systems to ensure long-lasting durability.

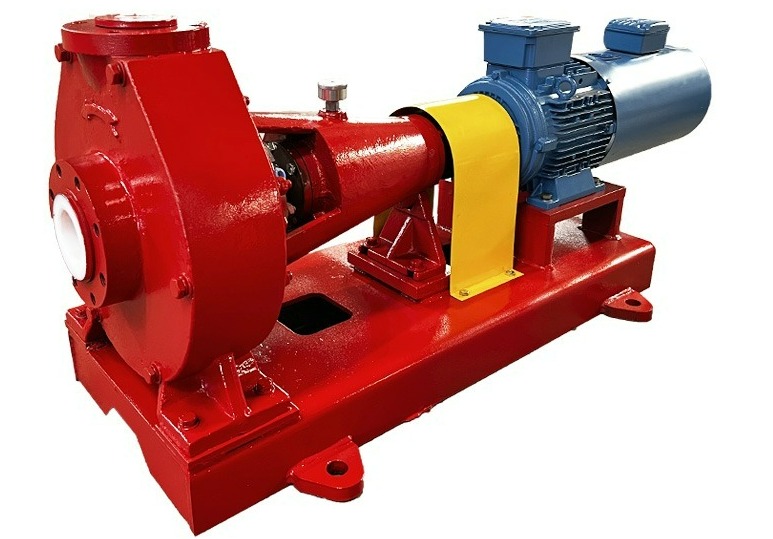

Wear-Resistant Pumps

Wear-resistant pumps, on the other hand, are designed to handle abrasive materials like slurry, sand, or gravel. These pumps are widely used in industries such as mining, construction, and dredging. To withstand the abrasive nature of the pumped media, wear-resistant pumps are constructed with materials like hardened steel or high-chrome alloys. Their robust construction prevents premature wear and enables them to maintain optimal performance even in demanding applications.

If you are looking for a reliable wear-resistant pump, consider [Slurry Pump Manufacturer]. They specialize in producing high-quality pumps that excel in handling abrasive fluids. Their pumps are designed with wear-resistant impellers and liners, reducing downtime and extending the overall lifespan of the pump.

Choosing the Right Pump

When comparing corrosion-resistant and wear-resistant pumps, it’s important to consider the nature of the substances being pumped. If you are dealing with aggressive liquids that tend to corrode standard pumps, a corrosion-resistant pump would be the ideal choice. On the other hand, if you are handling abrasive materials such as slurry or sand, a wear-resistant pump will provide superior longevity.

To ensure you select the right pump, it’s recommended to consult with a trusted supplier or contact the manufacturers directly. They can guide you in choosing the suitable pump, taking into account factors like fluid characteristics, operating conditions, and budget constraints.

In conclusion, both corrosion-resistant and wear-resistant pumps offer distinct advantages depending on the nature of your pumping needs. Whether you require a pump to handle corrosive fluids, abrasive materials, or both, it’s essential to select a high-quality pump from a reputable manufacturer like [Slurry Pump Manufacturer]. Making the right choice will ensure reliable performance, reduced downtime, and longer pump lifespan, ultimately leading to operational efficiency and cost savings in the long run.